Hardness Testing Services

Hardness testing is one of the most common quick indicators of the state of your material strength. You’ll be provided with a hardness value in various scales in order to point to the current processing status of your material.

We perform metallurgy hardness testing for customers in the forging, casting, hot wrought, cold drawn, machining, automotive, aerospace, and surface treatment industries.

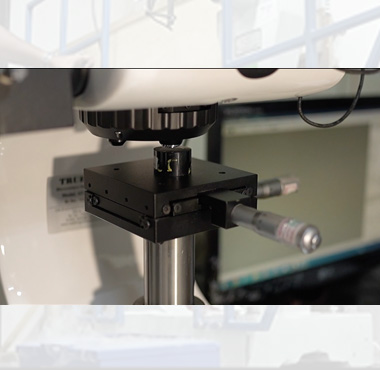

Hardness Testing Methods

Most production hardness testing is performed based on the same objective. A specific load is applied to a given indenter and the resistance the material has to its deformation is quantified as its hardness. When looking at the different testing methods (Brinell testing, Rockwell testing, Vickers testing), the difference is often a change in load or indenter. When choosing which test to use, the considerations should be where to test, the size of the material, and the expected hardness.

Brinell Hardness Testing

Represents the largest “bulk” hardness of the material. For this, larger samples with ample testing space are needed.

Rockwell Hardness Testing

Rockwell hardness testing focuses on a more localized area in a sample and can be taken on smaller samples as well.

Vickers Testing

Vickers testing and Knoop testing methods are performed on even smaller samples and represent micro-size areas of a given material.

Hardness Testing Lab Standards

VSP performs hardness testing to

♦ ASTM E10

♦ ASTM E18

♦ ASTM E92

♦ IS-1586 Part 1

♦ IS-1500 Part 1

♦ IS-1501 Part 1